Master Excel 2021: A Deep Dive into Professor Teaches Excel 2021

Master Excel 2021: A Deep Dive into Professor Teaches Excel 2021

Tired of feeling overwhelmed by Excel? Maybe you know the basics but want to harness the true power of pivot tables, macros, and complex formulas. Learning a robust program like Microsoft Excel can be daunting, but it doesn’t have to be.

That’s where a structured, interactive learning tool like Professor Teaches Excel 2021 comes in. It’s designed to transform you from a hesitant beginner into a confident, proficient user. Let’s break down what makes this training software so effective.

What is Professor Teaches Excel 2021?

Professor Teaches Excel 2021 is a comprehensive, interactive tutorial software designed to help you master Microsoft Excel. Unlike passive video tutorials, it offers a hands-on learning experience with a curriculum that’s perfect for both those just starting out and seasoned users looking to sharpen their advanced skills.

With a massive library of content and a practical approach, it simulates the real Excel environment, allowing you to learn by doing—without the fear of making mistakes in a live spreadsheet.

Key Features That Make Learning Excel Easy

So, what sets this software apart? Here are the standout features that deliver a top-tier learning experience:

- Over 200 Practical Lessons & Exercises: Go from basic spreadsheet creation and data entry to advanced functionalities like PivotTables, advanced formulas, data analysis, and macros. The curriculum is vast, ensuring you cover every feature you need to know.

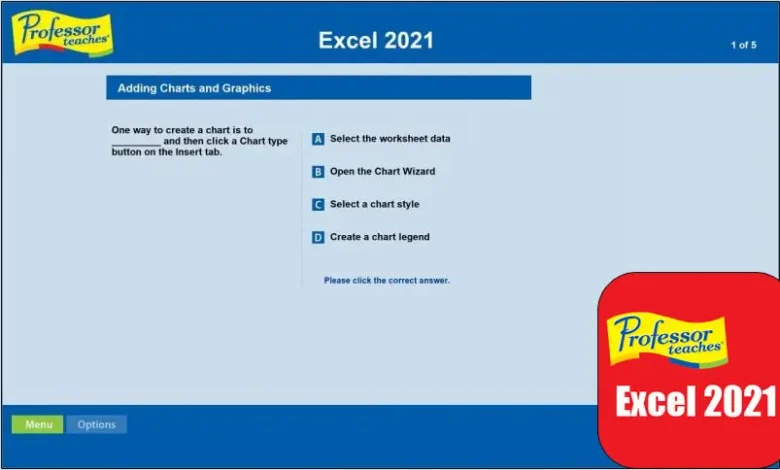

- A Truly Hands-On Training Environment: This is the core of the program. You don’t just watch; you do. The software provides a realistic, simulated Excel environment where you can practice tasks, experiment, and apply new skills risk-free. No more worrying about corrupting your actual work files!

- Clear, Detailed Explanations & Examples: Every concept is broken down with easy-to-follow explanations and real-world examples. This ensures you don’t just memorize steps—you understand the why behind them, cementing your knowledge.

- User-Friendly, Interactive Interface: The intuitive design makes it easy to navigate through the lessons and find exactly what you need to learn. You can progress at your own pace, quickly reviewing tricky sections or skipping ahead to more challenging topics.

Who Is This Software For?

Absolutely anyone looking to improve their Excel skills!

- Beginners will appreciate the step-by-step guidance starting from the absolute fundamentals.

- Intermediate Users can jump directly to specific lessons to fill knowledge gaps and learn new functions.

- Advanced Users will find value in mastering complex topics like macro creation and sophisticated data analysis techniques.

What You Need to Run It (System Requirements)

Before you get started, ensure your system is compatible. Professor Teaches Excel 2021 runs on:

- Operating System: Windows 11, Windows 10, Windows 8.1, or Windows 7

- Processor: Intel Pentium 4 or higher

- Memory: 2 GB of RAM or more

- Display: 1024 x 768 screen resolution or higher

- Installation: DVD-ROM drive (for physical copies)

Your Top Questions, Answered

Q: Is Professor Teaches suitable for someone who has never used Excel?

A: Yes! It is specifically designed to be beginner-friendly, with lessons that start with the very basics of navigating the interface and creating your first spreadsheet.

Q: Can I practice within the software itself?

A: Absolutely. The hands-on training mode is a safe, simulated environment where you can practice every lesson without using real Excel or real data.

Q: Are the lessons just videos, or are they interactive?

A: This is not a passive video course. The lessons are fully interactive, requiring you to complete tasks within the simulation, which is a far more effective way to learn and retain knowledge.

Final Verdict: Is Professor Teaches Excel 2021 Worth It?

Professor Teaches Excel 2021 is a powerful, feature-packed tool for anyone serious about conquering Microsoft Excel. Its learn-by-doing methodology, combined with an extensive library of lessons and a clear, user-friendly interface, makes it one of the most effective ways to learn at your own pace.

Whether you’re looking to boost your resume, improve your productivity at work, or finally understand those complex Excel functions, this software provides the comprehensive training you need to succeed.

Ready to unlock the full potential of Excel? Share your biggest Excel challenge in the comments below